PLC DCS Analog Input Module Redundancy

Price 15000 INR/ Piece

PLC DCS Analog Input Module Redundancy Specification

- Phase

- Single/Three Phase Compatible

- Connectivity Type

- Ethernet, Serial, Profibus, Modbus

- Control Type

- Digital

- Features

- Hot swap, Redundancy, Modular design, IEC compatibility

- Weight

- Approx. 350 grams

- Sensor Type

- Analog (Voltage/Current)

- Automation Grade

- Automatic

- Load Capacity

- Depend on Channel (typ. 420mA, 10V per input)

- Processor Type

- Microcontroller Based

- IP Rating

- IP20 or higher

- Remote Control

- Yes

- Cable Length

- User defined, usually up to 100m

- Frequency

- 50/60 Hz

- Drive Type

- Panel Mounted

- Speed Range

- Configurable

- Application

- PLC/DCS redundant analog signal input in industrial automation

- Mounting Type

- DIN Rail Mount

- Material

- Plastic, ABS, Metal

- Power

- 24 VDC / 110-240 VAC

- Temperature

- 0C to +60C

- Voltage

- 12-32 VDC

- Chassis Type

- Standard 19" or custom enclosure

- Configuration

- Software configurable via PC Suite

- Channels per Module

- 8, 16, or 32 channels (model dependent)

- Current Consumption

- Max. 300mA at 24VDC

- Hot Swappable

- Supported

- Response Time

- 5 ms

- Input Signal Type

- 4-20mA, 0-10V, 10V, RTD (Pt100/Pt1000 options available)

- Humidity

- 5% to 95% non-condensing

- Redundancy Support

- Dual redundant module operation, seamless switchover

- EMC Interference

- EN61000-6-2/4 compliance

- Diagnostics

- Built-in channel health and fault indication LEDs

- Compliance

- CE, RoHS

- Isolation

- Channel to Bus and Channel to Channel Isolation 1.5kV AC

- Storage Temp

- -40C to +85C

- Analog Input Resolution

- 12/16 bit ADC

PLC DCS Analog Input Module Redundancy Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About PLC DCS Analog Input Module Redundancy

This analog Input module board is used for interconnection of filed device analog signals like 4to 20 mA .0 to 10 VDC . It can be provixed with I solation and multiple channels

Usage/Application IndustrialModel Name/Number Analog IO Module interfacing boardNetwork Type PLC wiringStorage Temperature 85 Degree CelsiusUsage The Analog Input Module (AIN) is a key subsystem in the PLCSupply Voltage 24 VDCConsumption Current 20 mAFrequency 50HzInstallation Type DIN-Rail or Wall Mounting

Seamless Redundancy and Hot Swapping

The module's dual-redundant operation supports automatic switchover if a fault occurs, ensuring continuous signal acquisition. Each module is hot swappable, which means replacement or maintenance can be performed without system interruption. This robust architecture increases overall system uptime, essential in mission-critical industrial automation environments.

Versatile Analog Input Solutions

Offering models with 8, 16, or 32 channels, the module suits various applications from small to large-scale projects. It supports multiple analog input signals, including current, voltage, and RTD sensors like Pt100/Pt1000, with high-resolution 12/16-bit ADCs. Channel and bus isolation enhances safety and minimizes interference, maximizing signal integrity for precise process control.

FAQ's of PLC DCS Analog Input Module Redundancy:

Q: How does the dual redundancy feature enhance system reliability?

A: Dual module redundancy ensures that if the primary module fails, the backup module instantly takes over with seamless switchover. This architecture minimizes downtime and guarantees continuous, reliable data acquisition in industrial automation systems.Q: What types of analog input signals are supported by the module?

A: The module accepts 4-20mA current, 0-10V and 10V voltage inputs, and RTD signals (Pt100/Pt1000 options). This flexibility allows integration with a wide range of sensors commonly used in process control and monitoring.Q: When should I consider hot swapping a module, and is it safe to do so during operation?

A: Hot swapping is recommended during maintenance or replacement to avoid halting system operations. The module supports live insertion and removal, ensuring safety and uninterrupted system performance when properly conducted according to the manufacturer's guidelines.Q: Where can this analog input module be installed, and what mounting options are available?

A: The module fits standard 19-inch rack enclosures or custom cabinets and can be panel mounted or DIN rail mounted, making it suitable for diverse industrial automation installations in manufacturing plants, process industries, and utilities.Q: What is the configuration process for analog input channels using this module?

A: Channel configuration is performed via the dedicated PC Software Suite. Users can set input types, calibration, diagnostics, and communication protocols, optimizing the module's performance for specific operational requirements.Q: How do built-in diagnostics and fault indication LEDs benefit users?

A: Diagnostic LEDs provide immediate visual feedback on each channel's status, alerting operators to faults or health issues. This proactive monitoring shortens troubleshooting time and helps maintain optimal system performance.Q: What certifications and compliance does the module adhere to?

A: The module meets CE, RoHS, IEC, and EN61000-6-2/4 EMC standards, ensuring it conforms to global safety, environmental, and electromagnetic compatibility requirements for industrial automation equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Interface And Panel Accesories Category

UL 16 Channel Relay Board

Price 1600 INR / Piece

Minimum Order Quantity : 10 Pieces

Weight : Approx. 400g

Features : OptoIsolated Inputs for Noise Protection, LED Status Indicators, High Durability

Connectivity Type : Screw Terminal Blocks

Material : FR4 PCB, Flame Retardant, High Quality PCB Board

Phoenix Slim Relay Module

Price 920 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 30g

Features : Pluggable relay, LED indicator, Slim 6.2mm width, Isolation barrier

Connectivity Type : Screw terminal

Material : Polyamide PA66 housing

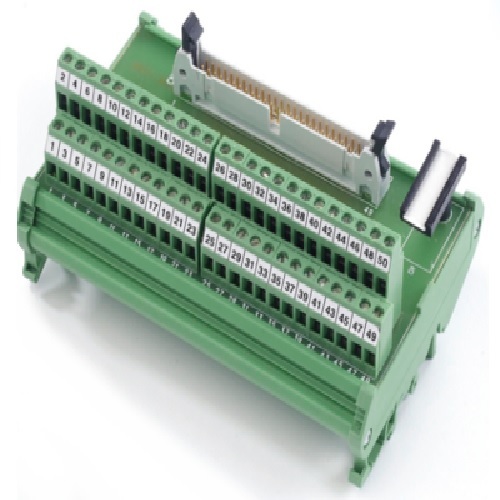

UL FLKM 40 Interface Module

Price 550 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 120 g

Features : Pluggable Interface, Vibration Resistant Design, Numbered Terminal Blocks

Connectivity Type : Screw Clamp Terminal

Material : Flame Retardant Polyamide (PA66)

Diode Oring Module

Price 750 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 250g

Features : Compact, Easy Installation, Low Forward Drop, High Current Handling, RoHS Compliant

Connectivity Type : Screw Terminal

Material : FR4 PCB, Electronic Components

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry