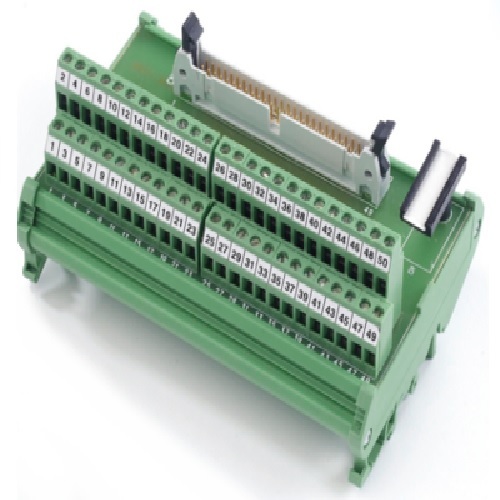

UL FLKM 40 Interface Module

Price 550 INR/ Piece

UL FLKM 40 Interface Module Specification

- Features

- Pluggable Interface, Vibration Resistant Design, Numbered Terminal Blocks

- Automation Grade

- Industrial Automation

- Control Type

- Passive

- Weight

- Approx. 120 g

- Application

- PLC Signal Interface / Control Cabinet Integration

- Mounting Type

- DIN Rail Mounting

- Cable Length

- User Defined (depends on installation)

- Load Capacity

- Per Terminal Up to 2.5A

- IP Rating

- IP20

- Phase

- Single Phase

- Frequency

- 50/60 Hz

- Connectivity Type

- Screw Clamp Terminal

- Material

- Flame Retardant Polyamide (PA66)

- Power

- Low Power Consumption (signal level)

- Temperature

- -20C to +50C Operating Range

- Voltage

- Max 250V AC/DC

- Compliance

- RoHS Compliant

- Connector

- Male 40-Pin D-Sub (DB40)

- Resistance to Flame

- UL94V-0 Rated

- Colour

- Grey

- Package Content

- FLKM 40 Module, Installation Manual

- Terminal Type

- Screw Type

- Dimensions

- Approx. 125mm x 90mm x 45mm

- No. of Channels

- 40 Channels

UL FLKM 40 Interface Module Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About UL FLKM 40 Interface Module

Passive Interface Modules are used to convert the conventional wiring into Modular Wiring. It consists of FRC Male connector at one side and screw type/screw-less terminals at the other side.

No. of Positions: 40Test Voltage: 500V between each channel.Standard/Approvals: PCB: Type tested STQC, IEC 61373, ANSI IPC 2221 2222, MIL 275B.Terminals: UL/CE CSA Standard.

Efficient Signal Management for Control Cabinets

The FLKM 40 Interface Module streamlines signal distribution in PLC-based control cabinets, enabling secure connectivity for up to 40 channels. Its pluggable, vibration-resistant interface simplifies integration and maintenance, while numbered screw terminals support organized wiring. Engineered for industrial environments, it stands out for reliable performance even under demanding conditions.

Industrial-Grade Safety and Compliance

This module uses flame-retardant PA66 material and boasts a UL94V-0 rating, making it a safe choice in high-risk environments. RoHS compliance and IP20 protection add assurance for global standards. The device's single-phase compatibility and low-power consumption meet modern automation requirements without compromise.

FAQ's of UL FLKM 40 Interface Module:

Q: How is the UL FLKM 40 Interface Module installed in a control cabinet?

A: The module is designed for DIN rail mounting, enabling swift and secure installation within PLC control cabinets. Simply attach the module to the rail and connect wires using the numbered screw clamp terminals as per the included installation manual.Q: What benefits does the flame-retardant polyamide construction offer?

A: The use of UL94V-0 rated PA66 provides superior fire resistance, enhancing safety in industrial environments. This material minimizes fire risk and contributes to the module's overall durability against harsh operating conditions.Q: Where can the FLKM 40 Interface Module be used?

A: It is ideal for industrial automation systems, especially in applications involving PLC signal interfacing and control cabinet integration. The module suits manufacturing plants, process automation setups, and electrical distribution boards that require organized signal management.Q: What is the process of connecting cables to the module?

A: Cables are connected using the screw clamp terminals on the module, which are individually numbered for accurate and easy identification. Users can define cable lengths according to the installation's requirements, ensuring flexibility and neatness in wiring.Q: When should the module be selected for automation projects?

A: Choose the FLKM 40 Interface Module when your automation project requires reliable, high-density channel connectivity, vibration resistance, and compliance with fire safety standards. It is particularly valuable where maintenance access and organized wiring are priorities.Q: What makes this interface module suitable for vibration-prone environments?

A: Its vibration-resistant design, robust housing, and secure DIN rail mounting ensure stable operation even in environments with significant mechanical movement, reducing the likelihood of signal interruption or loose connections.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Interface And Panel Accesories Category

AC Relay Module

Price 1100 INR / Piece

Minimum Order Quantity : 10 Pieces

Application : Industrial Automation, Electrical Control, Home Automation

Voltage : Input: AC 220V; Output: Up to AC 250V

Mounting Type : Panel Mount, DIN Rail Compatible

Material : FR4 PCB, Flame Retardant Plastic, Copper Tracks

UL DC Relay Module

Price 800 INR / Piece

Minimum Order Quantity : 10 Pieces

Application : Control of circuits, automation systems, industrial control panels

Voltage : 5V DC / 12V DC / 24V DC (as per variant)

Mounting Type : Panel Mount or DIN Rail Mount

Material : Plastic and PCB

Passive Interface Modules

Price 980 INR / Piece

Minimum Order Quantity : 1 Piece

Application : PLC interfacing, Signal distribution, Industrial automation, Field connections

Voltage : up to 250V AC/DC

Mounting Type : DIN Rail Mount, Panel Mount

Material : Polycarbonate, ABS or FR4 (PCB base), Flame Retardant

FTA Input Board Interfacing Card

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial Automation

Voltage : 5V DC

Mounting Type : Panel Mount

Material : PCB

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry