automation equipment

Price 1870 INR/ Piece

automation equipment Specification

- Features

- Energy efficient, modular design, user friendly interface

- Application

- Industrial process automation

- Mounting Type

- Floor / Panel Mounted

- Drive Type

- AC Servo / Stepper Motor

- Screen Size

- 7 inch HMI Touchscreen

- Control Type

- PLC Based

- Phase

- Single & Three Phase

- Processor Type

- High-speed industrial microcontroller

- Weight

- Approx. 90 kg

- Connectivity Type

- Wired / Ethernet

- Automation Grade

- Automatic

- Sensor Type

- Inductive/Photoelectric Sensor

- Load Capacity

- Up to 500 kg

- Frequency

- 50/60 Hz

- Speed Range

- 0.5 m/s to 4 m/s

- Cable Length

- 3-5 meters

- IP Rating

- IP54 / IP65

- Remote Control

- Yes

- Material

- Mild steel, Stainless steel

- Power

- 220-240 V, 50/60 Hz

- Temperature

- -10C to +55C operating range

- Voltage

- 220 V AC

automation equipment Trade Information

- Minimum Order Quantity

- 1 Piece

- Sample Available

- Yes

- Main Domestic Market

- All India

About automation equipment

Most of the "ASTRO" parameters can be set remotelyusing SMS queries .I.e. Output mode, Offset Hrs etc., UV, OV settings. Sunrise.

Relay Output can be override remotely using SMS query.

Energy Meter Functionality. Parameter like Load current,Supply voltage, Power, Energy can be known remotely.

With the help of "Auto Error Code Update"following

Onsite error can be know remotely during output event.

- Under Voltage

- Over Voltage

- Over Current

- Output actuator short.

- Load Open

Intuitive Control and Monitoring

The automation equipment features a user-friendly 7-inch HMI touchscreen and LED status indicators, ensuring operators can monitor and control processes efficiently. Ladder Logic support simplifies programming and operation, while the modular design allows for system expansion and easy integration with existing infrastructure. The device's built-in alarms promptly notify users of any issues for enhanced safety.

Versatile Industrial Application

Constructed from durable mild and stainless steel, this equipment is suitable for a wide range of industrial environments, including those with high humidity and fluctuating temperatures. Its air-cooled system and IP54/IP65 rating provide reliable protection, while multiple installation options-panel or floor mounting-offer flexibility for diverse automation needs.

Seamless Connectivity and Integration

Equipped with RS485, USB, and Ethernet communication ports, the automation equipment ensures robust and flexible data integration with existing networks. Remote control capability and support for both single and three-phase power make it adaptable to various operational requirements, increasing productivity for manufacturers, suppliers, exporters, and importers.

FAQ's of automation equipment:

Q: How does the automation equipment ensure seamless integration with existing industrial systems?

A: The equipment offers RS485, USB, and Ethernet connectivity, supporting easy integration into existing wired or Ethernet-based industrial networks. Its PLC-based control and Ladder Logic programming make it compatible with widely used automation standards, ensuring interoperability across systems.Q: What types of applications can this automation equipment handle effectively?

A: This solution is designed for industrial process automation, capable of managing control, measurement, and actuation processes in manufacturing, logistics, and other automated applications. Its robust construction, broad temperature and humidity tolerance, and versatility in mounting and power options accommodate diverse industrial settings.Q: When is installation service available and how can it be requested?

A: Installation services are offered on request across India for all clients, including exporters, importers, manufacturers, and suppliers. To arrange installation, contact our sales or support team during your equipment purchase or afterward via our official website or customer service hotline.Q: Where can this automation equipment be installed?

A: The device is engineered for both floor and panel mounting, offering flexibility for installation in control rooms, production floors, and other industrial environments. Its IP54/IP65 ingress protection ensures suitability for facilities requiring dust and moisture resistance.Q: What is the process for programming and operating the equipment?

A: Programming is accomplished using Ladder Logic, a widely utilized language in industrial automation. Operators use the 7-inch HMI touchscreen for configuration and monitoring, while LED status indicators and integrated audio-visual alarms assist in real-time operation and troubleshooting.Q: How does the embedded alarm system work, and what benefits does it offer?

A: The integrated audio-visual alarm system instantly alerts operators to irregularities or critical events. This proactive notification boosts workplace safety, minimizes response times for corrective action, and helps maintain uninterrupted production by preventing issues from escalating.Q: What are the benefits of using this automation device in an industrial setting?

A: Key benefits include energy efficiency, a modular and user-friendly interface, robust environmental resistance, and compatibility with both single and three-phase power. The equipment's high-speed microcontroller, advanced sensors, and remote control capability contribute to reliable, efficient, and scalable automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Interface And Panel Accesories Category

UL DC Relay Module

Price 800 INR / Piece

Minimum Order Quantity : 10 Pieces

Voltage : 5V DC / 12V DC / 24V DC (as per variant)

Frequency : DC (not applicable for frequency as pure DC)

Automation Grade : Automatic

Connectivity Type : Screw terminal

UL Relay Card

Price 600 INR / Piece

Minimum Order Quantity : 10 Pieces

Voltage : Up to 250V AC

Frequency : 50/60 Hz

Automation Grade : Automatic

Connectivity Type : Screw Terminal

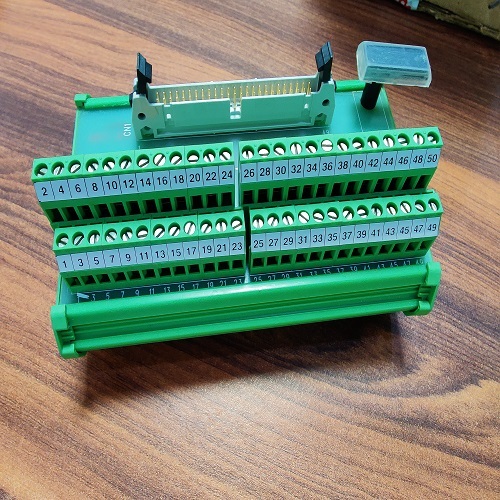

FTA Input Board Interfacing Card

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 5V DC

Frequency : 5060 Hz

Automation Grade : Automatic

Connectivity Type : Wired

UL FLKM 50 Passive Interface Modules

Price 650 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : Max 250 V AC/DC

Frequency : 50/60 Hz

Automation Grade : Industrial

Connectivity Type : Screw Terminal Blocks

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry