Call: 07971670477

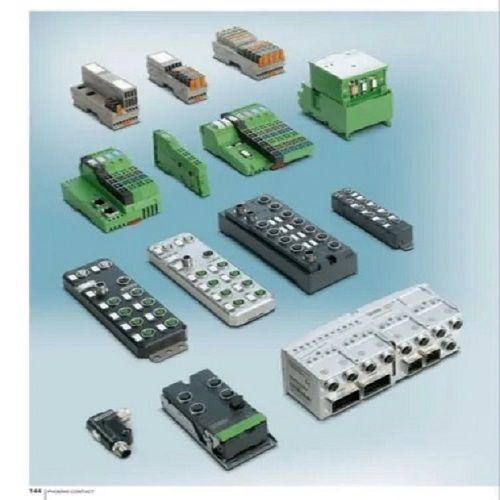

LioN-Link Modular IO Systems

Price 360 INR/ Piece

MOQ : 1 , , Piece

LioN-Link Modular IO Systems Specification

- Load Capacity

- Max. 500 mA per Channel

- Connectivity Type

- Fieldbus Protocols: Profibus-DP, CANopen, DeviceNet, EtherNet/IP, PROFINET IO, EtherCAT

- Frequency

- DC

- Control Type

- Fieldbus Controlled via Master Module

- Remote Control

- Yes

- Automation Grade

- Automatic

- Sensor Type

- Supports Digital and Analog Sensors

- Mounting Type

- DIN Rail and Direct on Machine

- Cable Length

- Up to 20 m from Master to last module

- Features

- Plug-and-play modularity, high diagnostic capability, robust design

- Speed Range

- Up to 12 Mbps (depending on Fieldbus)

- Drive Type

- Not applicable (IO System)

- Processor Type

- ARM-based Microcontroller

- Application

- Distributed Modular IO for Factory and Machine Automation

- IP Rating

- IP67 (Dust and Water Proof)

- Weight

- Approx. 300-800g (Depending on Module Type)

- Phase

- Single

- Material

- Industrial Grade Plastic and Metal Housing

- Power

- 24 V DC, max. 9 A through main supply

- Temperature

- -20C to +60C (Operation), -25C to +85C (Storage)

- Voltage

- 24 V DC

- Diagnostics

- Comprehensive status and error diagnostics via LEDs and Fieldbus

- Housing Material

- Glass-fiber reinforced plastic with metal parts

- Bus Connection

- Integrated fieldbus connection, plug-in technology

- Protection Class

- IP67, short-circuit and overload protection

- Ambient Humidity

- 5% to 95% (non-condensing)

- Connector Type

- M12, M8, Sub-D (as per module)

- Installation

- Tool-free module replacement and extension

- Input/Output Channels

- Up to 120 IO channels per link

- Signal Types Supported

- Digital Input, Digital Output, Analog Input, Analog Output, Special Modules

- Update/Programming

- Firmware updatable via fieldbus

- Module Expansion

- Max. 15 I/O modules per system

LioN-Link Modular IO Systems Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Days

About LioN-Link Modular IO Systems

Our customers highly preferred our offered product due to our unbeatable quality that inspires us towards providing LioN-Link Modular IO Systems. The provided product is manufactured using top quality material under our well-equipped infrastructure in the presence of extremely talented professionals. Our provided connector is fully insulated covered for heavy duty applicability. In addition to this, connector locking screw ensures superb electrical connection which provides non-interrupted performance. The offered LioN-Link Modular IO Systems is available in market-competent prices.

Robust Modular Expansion

The LioN-Link system allows easy and flexible expansion, with up to 15 I/O modules per system link. Its design enables users to replace or add modules tool-free, minimizing downtime and supporting evolving automation requirements. Robust enclosure materials ensure long-term durability, even in harsh industrial environments.

Comprehensive Signal and Diagnostic Support

This IO system seamlessly integrates a wide range of input and output types, including digital, analog, and special modules. Advanced diagnostics via LEDs and fieldbus feedback allow quick identification of errors or faults, boosting system reliability and simplifying maintenance for engineers and operators.

Flexible Connectivity and Fieldbus Integration

With support for major fieldbus protocols like Profibus-DP, CANopen, DeviceNet, EtherNet/IP, PROFINET IO, and EtherCAT, the system can be effortlessly integrated into almost any automation architecture. M12, M8, and Sub-D connectors add to the flexibility, ensuring compatibility with common industry cabling and sensors.

FAQ's of LioN-Link Modular IO Systems:

Q: How can I expand the LioN-Link Modular IO System in my automation setup?

A: You can expand your LioN-Link Modular IO System by adding up to 15 IO modules per system link. Expansion is tool-free, so modules can be replaced or extended quickly-enabling scalable configurations while minimizing machine downtime.Q: What types of input and output signals are supported by LioN-Link IO modules?

A: The system supports a broad range of signal types, including digital inputs and outputs, analog inputs and outputs, and special modules. This allows integration of both traditional digital/analog sensors and more specialized industrial signals.Q: When is it necessary to update the firmware on the LioN-Link IO modules?

A: Firmware should be updated whenever there are new software releases for bug fixes, added functionalities, or compatibility improvements. Updates can be performed remotely via the fieldbus connection, keeping devices current without manual intervention.Q: Where can LioN-Link Modular IO Systems be installed?

A: With an IP67 rating for dust and water resistance, LioN-Link modules are suitable for mounting directly on machinery or DIN rails in industrial settings where environmental robustness is essential. The compact, durable design ensures reliable operation in harsh conditions.Q: What is the process for diagnosing errors or faults in the system?

A: Comprehensive status and error diagnostics are available through integrated LEDs on each module and through fieldbus communication. This enables fast identification and localization of faults, expediting troubleshooting and reducing system downtime.Q: How does using LioN-Link Modular IO benefit factory and machine automation?

A: This system provides flexible scalability, high diagnostic transparency, quick installation, and robust protection, all of which improve system uptime, reduce maintenance effort, and enable future-proof automation solutions in both centralized and distributed scenarios.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in I-O System Category

I/o Systems For Field Installation

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 5060 Hz

Processor Type : 32bit ARM Processor

Phase : Single Phase

Power : 24 VDC, 0.5A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry