Anybus X Gateway

Price 12000 INR/ Piece

Anybus X Gateway Specification

- Product Type

- Industrial Protocol Converter/Gateway

- Number of Channels

- 2

- Call Control Protocol

- Proprietary (depends on connected networks)

- Frequency (MHz)

- 50-60Hz (power frequency), not RF

- Storage Temperature

- -40C to +85C

- Network Connection Methods

- Ethernet, CANopen, Profibus, Modbus-TCP, DeviceNet, and more

- Power

- 24 V DC (18-30 V DC)

- Dimension (L*W*H)

- 120 x 75 x 27 mm

- Weight

- Approx. 150 g

- Power Supply

- 24 V DC

- Material

- Industrial grade plastic/metal housing

- Size

- 120 x 75 x 27 mm

- Led Indicator

- Power, Network Status, Communication Status

- No. of Ports/Pins

- 2 main network interfaces, 1 power terminal

- Range

- Depends on network standard (typically up to 100 m Ethernet)

- Usage

- Industrial automation network integration

- Color

- Blue and grey

- Height

- 27 mm

- Model

- X-Gateway

- Protection Class

- IP20

- Humidity

- 10-95% RH (non-condensing)

- Data Rate

- Up to 1Gbit/s (depends on network)

- Operating Temperature

- -25°C to +60°C

- Diagnostics

- Integrated web server and diagnostics

- Configuration

- Via USB or Ethernet

- Baud Rate

- Up to 12 Mbit/s (depends on protocol)

- Current Consumption

- typically 150 mA at 24 VDC

- Mounting Type

- DIN rail

- Isolation

- Galvanic, between network ports

- Supported Protocols

- PROFIBUS, PROFINET, EtherNet/IP, Modbus TCP, CANopen, CC-Link, etc.

Anybus X Gateway Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Anybus X Gateway

The X-gateway allows you to seamlessly inter- connect PLC control systems and their connected devices } The data transmission between the two networks is completely transparent. } Over 300 different network combination (Master, slave, Adapter, I/O device, Server) } Connects different PLC system (Siemens, Rockwell, Schneider, Mitsubishi, Omron, Beckhoff ) } Max 512Bytes Of Input and 512 bytes of output data } I/O data transfer with average through put between network of 10-15 ms } Configuration via USB using the included Anybus Configuration Manager-No programming required } IT functions such as dynamic WEB Server, supporting downloadable customer specific web pages. } Fast, dynamic transfer of Fieldbus data to e.g. SCADA/HMI / Enterprise level systems based on Microsoft Windows, via the included Anybus OPC server } Robust stand-alone housing for use in harsh industrial environments } Remote monitoring and diagnostic feature for most Ethernet version Via an Integrated WEB Sever } Anybus Master Configuration tool included free of charge with a Profibus, Device Net or Ethernet/IP Master/Scanner.Robust and Versatile Design

The Anybus X-Gateway is engineered to operate reliably in harsh industrial environments with a wide operating temperature range (-25C to +60C) and robust IP20 protection. Its compact DIN rail-mountable housing allows for easy installation within control cabinets while providing galvanic isolation to safeguard network integrity and personnel safety.

Seamless Network Integration

Connectivity is made effortless with support for major protocols including PROFIBUS, PROFINET, EtherNet/IP, Modbus TCP, CANopen, and many others. Its two independent network channels enable flexible integration between different automation networks, allowing for maximum versatility in industrial applications.

Easy Configuration and Diagnostics

Configuration is straightforward via USB or Ethernet interfaces, catering to various user preferences. An integrated web server provides real-time diagnostics and status information, assisting users with maintenance and troubleshooting, and reducing system downtime. Clearly visible LED indicators display power, network, and communication statuses.

FAQs of Anybus X Gateway:

Q: How do I configure the Anybus X-Gateway for my network integration needs?

A: The Anybus X-Gateway can be configured using either a USB or Ethernet connection to your computer. After connecting, use the provided configuration tools or the integrated web server interface for simple setup and parameter adjustments tailored to your specific network protocols.Q: What protocols and network types does the X-Gateway support?

A: The X-Gateway supports a broad spectrum of industrial protocols, including PROFIBUS, PROFINET, EtherNet/IP, Modbus TCP, CANopen, CC-Link, and DeviceNet, among others. This ensures compatibility with a wide range of automation equipment and network architectures.Q: When is the best situation to use the Anybus X-Gateway in an industrial setting?

A: The X-Gateway is ideal when integrating devices or subsystems that use different communication protocols within a factory or process automation environment. It is particularly valuable for system upgrades, expansions, or when linking newer and legacy networks.Q: Where should the X-Gateway be installed within an automation system?

A: Install the Anybus X-Gateway on a DIN rail within a control panel or automation cabinet. Ensure it is placed in a location with adequate ventilation, within the specified temperature and humidity ranges, and near relevant network terminals for easy cabling.Q: What are the diagnostic features available on the X-Gateway?

A: The device features an integrated web server that provides real-time network diagnostics and device status. Additionally, it includes LED indicators for power, network status, and communication status, facilitating quick troubleshooting and maintenance.Q: How does galvanic isolation benefit the operation of the X-Gateway?

A: Galvanic isolation between the network ports prevents electrical interference and ground loops, ensuring signal integrity and protecting both the device and connected equipment from potential electrical faults.Q: What are the main benefits of using the Anybus X-Gateway for industrial automation?

A: Key advantages include seamless multi-protocol network integration, robust and compact industrial design, easy configuration, integrated diagnostics, and enhanced data throughput (up to 1 Gbit/s on certain networks). This aids in process optimization and reduces engineering efforts in complex automation environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ethernet And IIOT Category

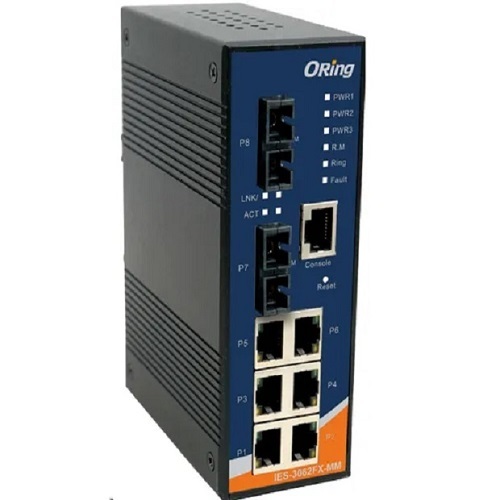

ORING IES-3062FX-MM-SC

Price 19000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 54 x 142 x 105 mm

Material : Metal (IP30rated aluminum enclosure)

Color : Silver

Product Type : Industrial Managed Ethernet Switch

16 PORT LIU BOX MULTI MODE

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 305mm x 210mm x 45mm

Material : Powder Coated Metal

Color : Grey

Product Type : 16 Port LIU Box Multi Mode

4 PORT LIU BOX SINGLE MODE

Price 1400 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 130mm 110mm 35mm

Material : Powder Coated Mild Steel (MS)

Color : Grey

Product Type : 4 Port LIU (Light Interface Unit) Box

16 PORT LIU BOX SINGLE MODE

Price 2500 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard 19 Inch Rack Mount

Material : Cold Rolled Steel Sheet

Color : Grey

Product Type : Fiber Optic LIU Box

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry