Call: 07971670477

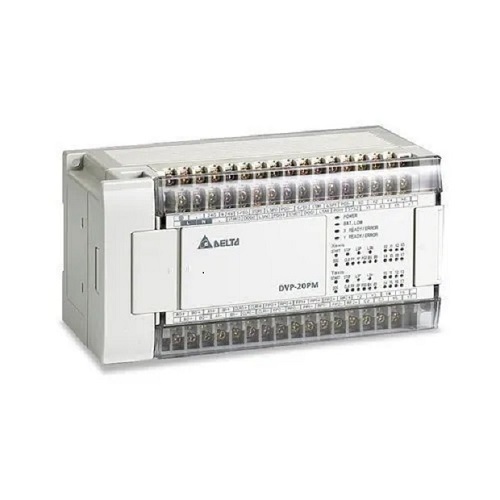

DELTA AC DRIVE

Price 21000 INR/ Piece

MOQ : 1 Piece

DELTA AC DRIVE Specification

- Efficacy

- High Efficiency

- Ambient Temperature

- -10C to 50C

- Horse Power

- 1 HP

- Torque

- Constant Torque

- Sealed Type

- IP20

- Motor Type

- AC Motor Drive

- Noise Level

- <65dB

- Rated Voltage

- 400 V

- Current Type

- AC

- Power Rating

- 0.75 kW

- Standard

- IEC 61800-5-1

- Poles Number

- Variable

- Features

- Digital Display, Easy Operation, Space Saving

- Starting Type

- Soft Start

- Rated Frequency

- 50/60 Hz

- Cooling Method

- Air Cooled

- Voltage

- 380-480 V AC

- Product Type

- AC Drive

- Output Power

- 0.75 kW

- Frequency (MHz)

- 50/60 Hz

- Protect Feature

- Overload, Over Current, Over Voltage, Under Voltage, Short Circuit

- Phase

- Three Phase

- Speed

- Variable

- Power

- 750 W

- Color

- Grey/Black

- Dimension (L*W*H)

- 110 x 125 x 180 mm

- Weight

- 2.5 kg

- Mounting Type

- Panel Mount

- IP Rating

- IP20

DELTA AC DRIVE Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About DELTA AC DRIVE

With modern power electronics and advanced microprocessor technology, Delta's AC Motor Drives are able to efficiently control motor speed, improve machine automation and save energy. Taking advantage of our strong position in power electronics technology, Delta's VFD Series of AC motor Drives has evolved rapidly. Each Drive series is designed to meet specific application needs. Our AC Drives accurately control speed and torque, smoothly handle an increased load, and provide numerous custom control and configuration operating modes. Our AC Motor Drive product line provides a full range of motor control technologies and is used throughout a wide range of industries, to enhance and improve machine automation.Advanced Control and Protection

The DELTA AC Drive offers both V/F and sensorless vector control methods to provide precise, variable speed regulation for AC motors. Multiple protective features, such as overload, overcurrent, and motor PTC thermistor support, ensure operational safety and equipment longevity in demanding industrial settings.

User-Friendly Operation

Equipped with a bright LED panel and soft start feature, the drive promotes easy parameter adjustment and monitoring. Quick acceleration/deceleration capabilities (0.1-6000 seconds) allow seamless adaptation to various industrial processes, improving productivity and efficiency.

Versatile Industrial Applications

Designed for industrial automation, this AC drive is ideal for conveyors, pumps, fans, and HVAC systems. Its compact design saves installation space, while panel mount capability and IP20 enclosure provide flexibility and durability in diverse environments.

FAQ's of DELTA AC DRIVE:

Q: How does the DELTA AC Drive support communication with industrial control systems?

A: The DELTA AC Drive features RS-485 ports that support Modbus protocol, enabling seamless integration with fieldbus networks and PLCs for remote monitoring, parameter configuration, and efficient control in automation environments.Q: What are the benefits of choosing sensorless vector control in this AC drive?

A: Sensorless vector control offers precise motor speed and torque regulation without the need for external sensors. This enhances energy efficiency, allows stable operation under varying loads, and reduces both maintenance and setup complexity.Q: When should I use the built-in braking unit of the DELTA AC Drive?

A: The built-in braking unit is essential when your application requires rapid deceleration, such as conveyor stop events or emergency halts. It safely dissipates energy, protecting both the motor and drive from potential damage during quick stops.Q: Where can the DELTA AC Drive be installed, considering its enclosure and size?

A: This drive comes in a compact form factor (110 x 125 x 180 mm) and ABS plastic enclosure with an IP20 rating, making it suitable for enclosed, ventilated industrial panels or control cabinets where space and accessibility are priorities.Q: How does the DELTA AC Drive ensure motor protection under varying operational conditions?

A: The drive supports PTC thermistor protection, guarding motors against overheating. It also provides comprehensive fault protection against overload, overcurrent, overvoltage, under voltage, and short circuit occurrences, thereby promoting safe operation.Q: What process adjustments can be made using the DELTA AC Drive's display panel?

A: Operators can easily set acceleration and deceleration times (0.1 to 6000 sec), adjust speed, monitor performance, and access operational diagnostics through the LED panel, ensuring tailored control for different industrial processes.Q: What are the primary usage and benefits for industries using this AC drive?

A: Industries benefit from high reliability, energy-efficient motor control, easy installation, and reduced downtime. Applications in conveyor, pump, HVAC, and fan systems achieve improved performance, safer operation, and lower operational costs with the DELTA AC Drive.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Delta Servo Motor Category

CNC Controllers Delta Solutions

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Standard Grey

Product Type : Other, CNC Controllers

Phase : Other, 3 Phase

Delta Servo Motor

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Product Type : Induction Motor

Phase : Single Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry